描述

Equipment features:

- High quality appearance, the body adopts a curved shape, the surface is treated with mist stripes, and a flat non reaction handle is used, which is easy to operate, safe and reliable.

- A rectangular laminated glass viewing window can be used for observing the test object during the experiment. The window is equipped with an anti sweat electric heating device to prevent water vapor from condensing and water droplets, and a high brightness PL fluorescent lamp to maintain illumination inside the box. The double-layer isolation and airtightness of the box door can effectively isolate internal temperature leaks.

- The insulation system uses ultra-fine glass fiber to fill the insulation area, and non-metallic high and low temperature resistant materials are used for the connection parts of the inner and outer tanks, effectively reducing temperature conduction; The sealing of the box door adopts refined silicone rubber, so that there is no aging and hardening phenomenon under high and low temperature conditions, and the sealing performance is more reliable; The humidification method adopts isolated humidification;

- Equipped with an external water supply system, it is convenient to supplement the humidification bucket water supply and automatically recycle it for use.

- The compressor circulation system adopts Japanese brands, which can effectively remove lubricating oil between the condenser tube and capillary tube, and the entire series uses environmentally friendly refrigerants (R23 R404、R507)。

- The controller adopts an imported touch display screen, which can simultaneously display measured values, set values, and time.

- The controller has multi-stage program editing and can be used for quick (OUICK) or slope (SLOP) control of temperature and humidity.

- The built-in mobile pulley is easy to move and place, and has strong positioning screws to fix the position.

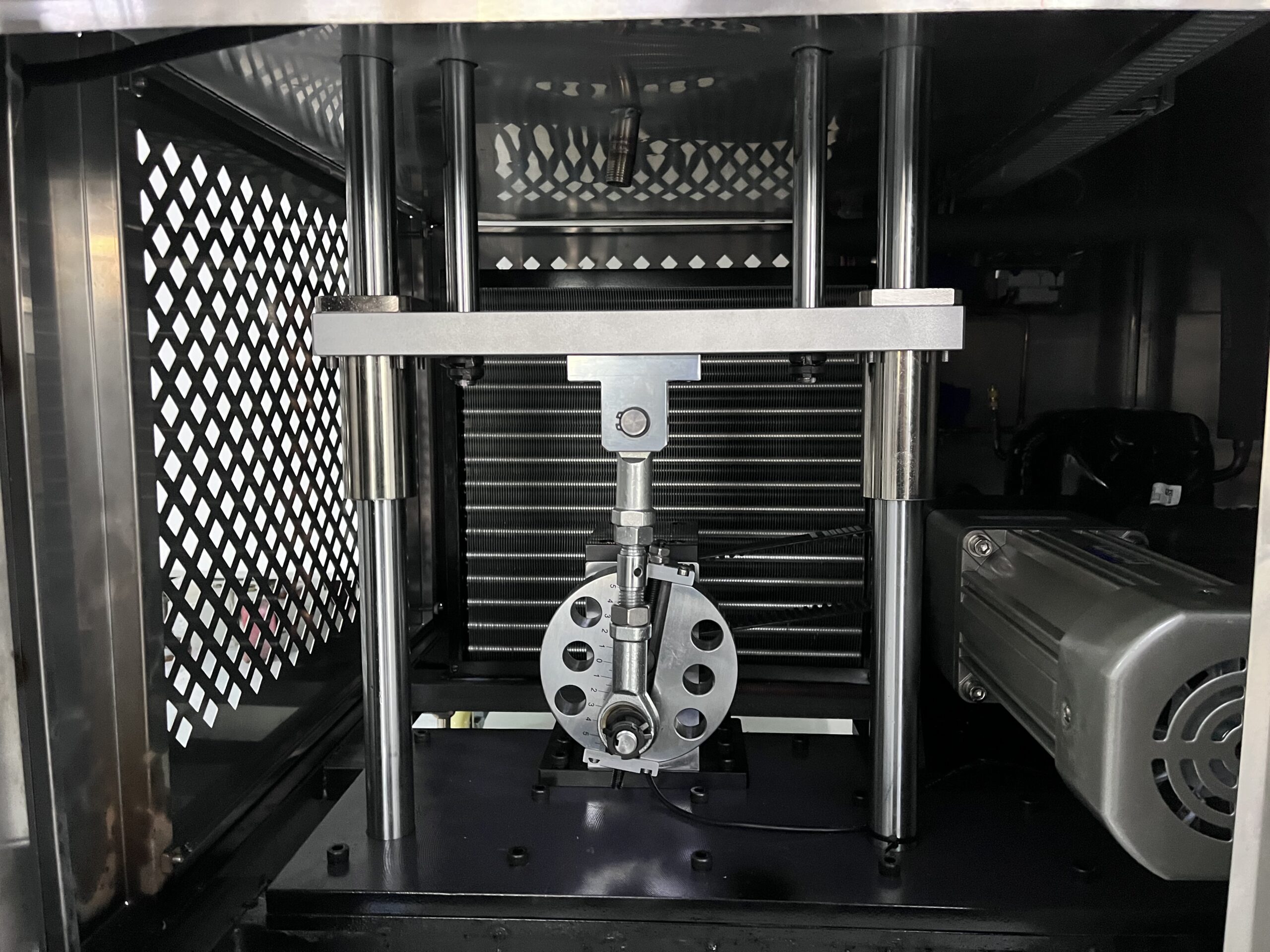

- The air supply circulation system adopts a low-noise, long-life, air-conditioned special fan, with multi wing centrifugal blades as the wind turbine.

Meets standards:

- GB/T2423.1-2008 “Environmental testing for electrical and electronic products – Part 2: Test methods – Test A: Low temperature”

GB/T2423.2-2008 Environmental Testing for Electrical and Electronic Products Part 2: Test Methods Test B: High Temperature

- GB/T2423.3-2006 “Environmental testing for electrical and electronic products – Part 2: Test methods – Test Cabs: Constant humidity heat test”

- GB/T2423.4-2008 “Environmental testing for electrical and electronic products – Part 2: Test methods – Test Db – Alternating humidity heat (12h+12h cycle)”

- GB10589-2008 Technical Conditions for Low Temperature Test Chambers

- GB11158-2008 Technical Conditions for High Temperature Test Chambers

- GB10586-2006 Technical Conditions for Damp Heat Test Chambers

- GJB150.3-1986 High Temperature Test

- GJB150.4-1986 “Low temperature test”

- GJB150.9-1986 “Damp Heat Test”

(The load per cubic meter shall not exceed the thermal capacity of 20kg/m3 steel, and there shall be no active thermal load during the wet heat test

Aplication industry:

Suitable for testing the quality of electronic, plastic products, electrical appliances, instruments, food, vehicles, metals, chemicals, building materials, aerospace, medical… and other products.

Detailed parameters::

| Model | KH-80

(A~G) |

KH-150

(A~G) |

KH-225

(A~G) |

KH-408

(A~G) |

KH-608

(A~G) |

KH-800

(A~G) |

KH-1000

(A~G) |

| Internal dimensions WxHxD (cm) | 40x50x40 | 50x60x50 | 50x75x60 | 60x85x80 | 80x95x80 | 100x100x80 | 100x100x100 |

| External dimensionsWxHxD (cm) | 90x136x94 | 100x146x104 | 100x161x117 | 110x171x137 | 130x181x137 | 150x186x137 | 150x186x157 |

| temperature range | -40℃~+150℃(150℃)

(A:+25℃ B:0℃ C:-20℃ D:-40℃ E:-50℃ F:-60℃ G:-70℃) 【Optional configuration】 |

||||||

| Humidity range | 20%~98% R.H. (10% -98% R.H/5%~98% R.H are special selection conditions) | ||||||

| Temperature and humidity analysis accuracy/uniformity | ±0.1℃;±0.1%R.H./ ±1.0℃;±3.0%R.H. | ||||||

| Temperature and humidity control accuracy/fluctuation | ±1.0℃;±2.0%R.H./ ±0.5℃;±2.0%R.H. | ||||||

| Heating/cooling time | About 4.0 ℃/minute; Approximately 1.0 ℃/minute (a decrease of 5-10 ℃ per minute is a special selection condition) | ||||||

| Internal and external materials | The entire machine is treated with SUS 304 # stainless steel plate mist finish, and the inner box is made of stainless steel | ||||||

| Insulation material | High temperature resistant and high-density vinyl chloride acetate foam insulator material | ||||||

| Protective devices | No. 1 is not available

No.2 overtemperature protection Over temperature protection of humidifier cylinder 3 No.4 humidity over temperature protection 5th and 1st compressor protection 6th and 2nd compressor protection No.7 refrigerant high-pressure protection Water tank without water protection |

||||||

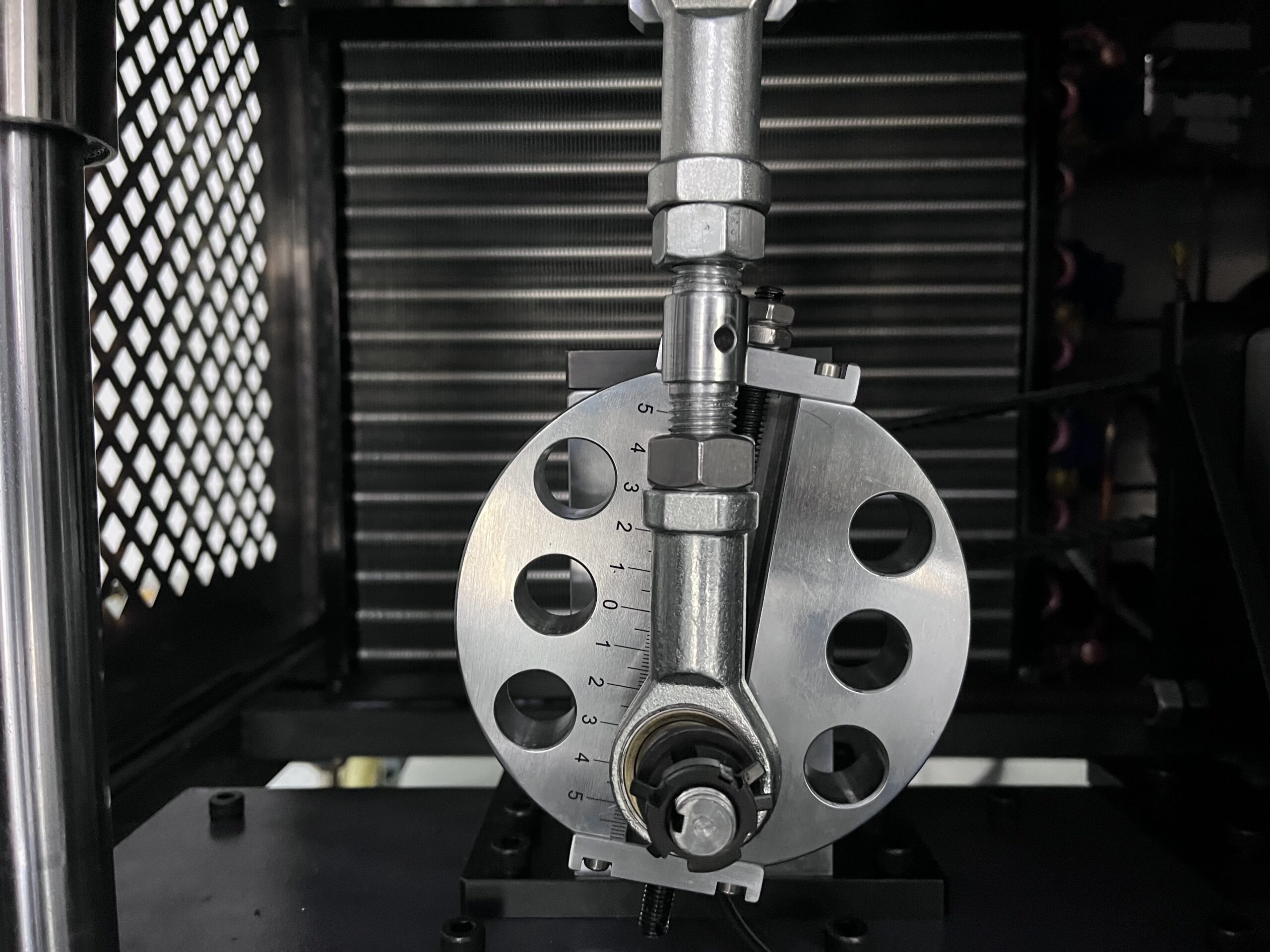

| accessory | Recorder (optional), viewing window, 50mm test hole PL box lights, partitions, dry and wet ball gauze | ||||||

| controller | Imported touch screen controller | ||||||

| Power supply | 1Φ 220VAC±10% 50/60Hz & 3Φ 380VAC±10% 50/60Hz | ||||||

评价

目前还没有评价